Overseeing soil moisture levels accurately through irrigation systems is essential to increasing crop yield and preserving water. By accounting for soil moisture variability, farmers will be able to manage their irrigation systems better to utilize the necessary amount of water at the right time. By precisely scheduling the irrigation systems, our product can help avoid under or over watering. In order to do so, our product utilizes capacitance-based soil moisture sensors.

Our product proposes an innovative approach to conserve water by carefully measuring the amount of moisture in the soil, and activating precisely timed solenoid valves to keep the soil at its optimal moisture levels for the given corn crop to produce the max yield. In our prototype, we are proposing a solution for a farmer who grows corn crops, and this technology will decrease water utilization, and at the same time, it would help increase crop yield. Our product will also take into account the variability of water consumption based on the soil type, crop type, weather conditions, and stage of growth of the crop because these are all important influencing factors that contribute to the quality of corn production.

|

|---|

|

|

|

|

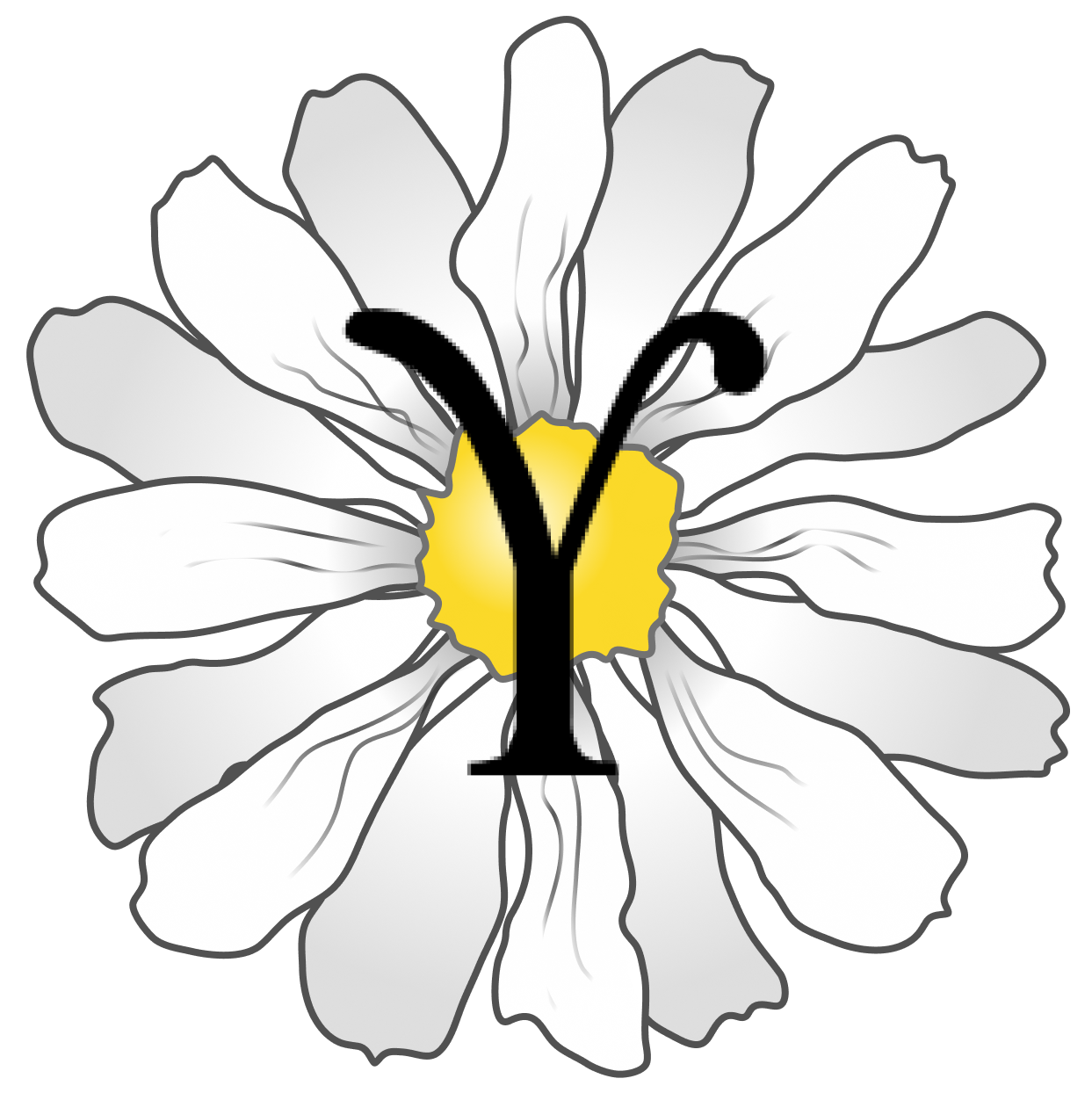

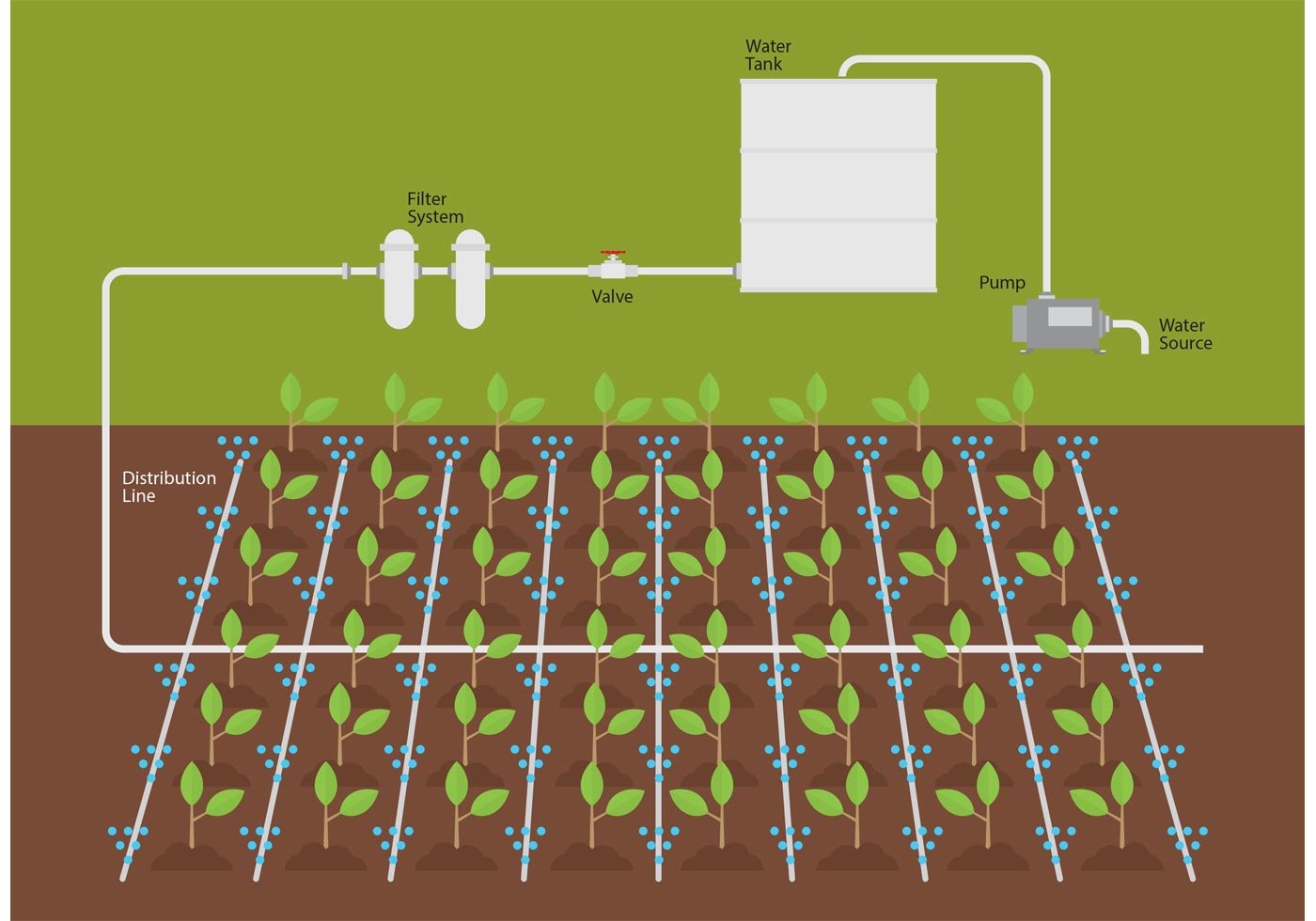

Pre-existing Drip Irrigation System: A drip irrigation system includes drip lines in rows of 300 - 600 feet. Drip lines are often spaced 12 - 18 inches from each other. The emitters, spaced 6 - 12 inches, in the drip lines are where the water exits out into the field. In the case of our prototype, we are modeling our product based on a system that has drip lines spaced 12 inches apart, and emitters spaced 12 inches apart as well.

Capacitive Moisture Sensors: The 16 sensors have a detection radius of 4.1 cm, and they are able to work by sensing the change in capacitance due to moisture in the soil. This sensor is more durable than traditional resistive moisture sensors because it is less prone to corrosion.

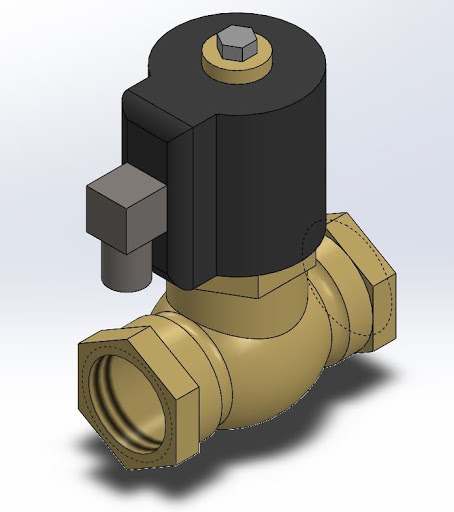

Solenoid Valves: The 4 plastic water solenoid valves have an operational voltage of 12V, but they can stretch to running on as low as 6V. This makes them good to use on spaced-out fields. They have two ½” nominal non-taped national pipe outlets.

Arduino Mega: This microcontroller receives data from the moisture sensors in the field, and it then determines if the soil is wet/dry based off of the data. If the sensors read dry, the Arduino will signal the solenoid valves to turn water on to the corresponding drip lines. Because this microcontroller has 16 analog pins, we are utilizing each one so that we have a total of 16 capacitive moisture sensors being controlled by it.

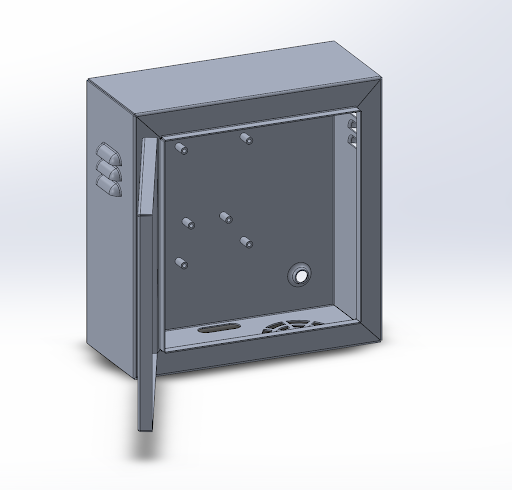

Enclosure: This serves as a housing for the Arduino Mega, and it is made out of sheet metal. It has vents to allow for aeration and to prevent condensation from collecting inside the enclosure. It also has countersink emboss for mounting.

Growth Phase Cycle Software: Our product comes with a web application in which farmers can update which cycle of growth their crop is in. The hardware will adjust how sensitive the system should be to moisture to give the correct amount of water for that phase.

Our team aspires to create a precise automation mechanism for drip irrigation systems in order to conserve freshwater and increase corn crop yields, thus we work diligently to bring this dream into fruition. We also prioritize a user-friendly interface, because we know that it is intimidating to have to sift through a handful of numeral readings from the moisture sensors and try to make sense of it. This is why our team has poured a lot of effort into creating a web application that makes access to your field data easy to read. We also trust our farmers working diligently in the fields every day, and understand that no one knows the ins and outs of corn better than they do. This is why we are putting the controls in their hands for deciding what growth stage their corn crops are in, and they will have easy access to updating that information on the web application.